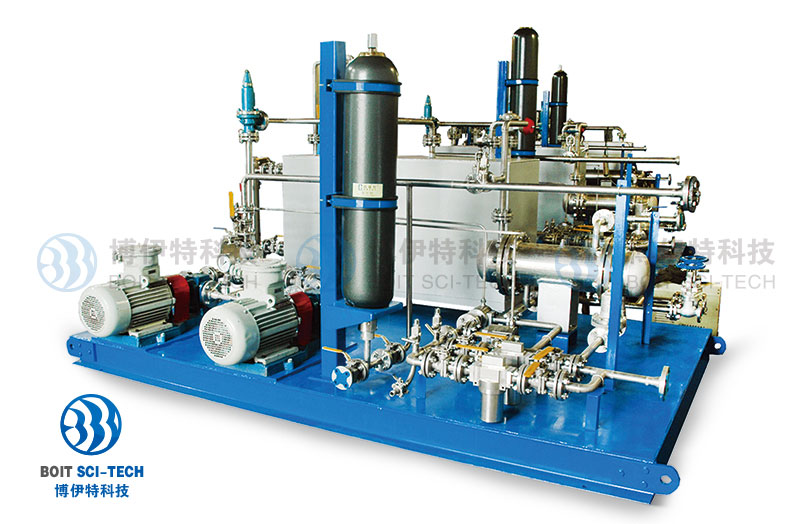

The sealing liquid pump unit is the large-sized hydraulic pressure unit specially equipped for the mechanical seal under pressure on the pump or reaction still. It can provide the clean, cooling and under-pressure sealing liquid (based on different working condition of mechanical seal, the sealing liquid can be oxalic acid, mineral oil and water) for mechanical seal. The sealing liquid from the mechanical seal will return to the oil tank at normal pressure after filtration and cooling. It is an open circulatory system, which completely meets API614 standard. The pump unit produced by our company won good comments from the customers relying on reasonable design, stable performance and reasonable price. Now, several sets of sealing liquid units produced for Eagleburgman has stably and reliably run in each factory. According to various special system parameters of the customers, the customers can order the sealing liquid pump unit from our company.

Working Principle:

After the motor drives the gear pump to absorb oil, the sealing liquid under pressure will enter into the mechanical annular seal space via the one-way valve, pressure transmitter and flowmeter. After the sealing liquid flows out of the mechanical annular seal space, the sealing liquid will return to oil tank via the pressure regulating valve (can adjust the pressure of system sealing liquid), liquid control one-way valve, filter and cooler and finish the circulation of major loop. The system is equipped with safety relief valve. Namely, when the system pressure exceeds the pressure set for relief valve (can adjust on spot), the oil outlet by the gear pump will return to the oil tank via the overflow valve in order to realize the purpose to protect the whole system (the set pressure of overflow valve is higher than the work pressure of system). The energy accumulator is the energy storage element. It can realize the function to reduce the pulsation and parking pressure maintaining. When the pump stops accidentally, the energy accumulator, one-way valve and liquid control one-way valve will work together to ensure the pressure of sealing liquid is higher than the pressure of pump cavity in some time and prevent the invalidity of mechanical seal because of back pressure.

Chinese

Chinese English

English